The sink in the kitchen will have a lot of problems after a long time. For example, rust, mildew, watermark, scratch, water leakage, big smell, blockage and so on. If you let these problems go and face these psychological problems every day, some problems are more likely to become hidden dangers if they are not solved. Therefore, I will write an article here to tell you some problems and reasons of stainless steel sink and the solutions to the problems,such as rust, watermark or scratch on the kitchen sink.

No one can guarantee that the stainless steel kitchen sink, even if it is made of SUS304, will not rust. Because there are many reasons for rust, it also has a great relationship with personal use habits, environment and so on.

For example, the tank is often exposed to corrosive liquids such as salt water and acid water, which is not cleaned in time, and even the tank is soaked with sewage for a long time. Or in coastal cities, the ventilation of kitchens is relatively poor, and the water around the sink is relatively humid, which may make the sink slowly produce rust, and then erode the sink and cabinet.

The watermark in the stainless steel sink is generally the mark left by the water stain in the sink after natural volatilization. Tap water is usually disinfected by adding some chlorine in the water plant. A small amount of tap water accumulates on the surface of the stainless steel sink and volatilizes naturally. After long-time precipitation, chlorine will be adsorbed on the purification membrane on the surface of stainless steel, and then a watermark will be formed.

As for the scratch of stainless steel sink, this is a problem that can not be completely avoided. Because the kitchen sink is the most frequently used utensil in kitchen life. All pots and pans are washed in the sink. Collision friction is essential. It can be said that scratch is the most widespread disadvantage of stainless steel sink.

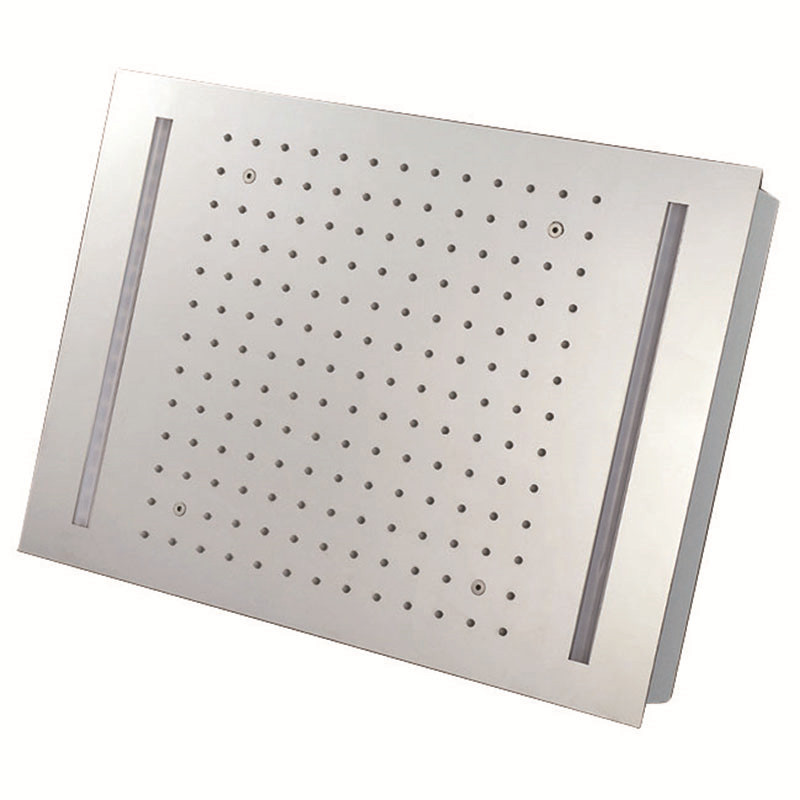

The surface treatment of stainless steel sink is divided into four processes: wire drawing, mirror light, snowflake sand and matte.

However, in these surface treatments, wire drawing is a common process on household appliances. The process effect is that there are uniform and fine textures on the surface of the stainless steel sink, which feels silky and smooth. The function of the tank texture can ensure the smooth drainage of the tank, prevent the tank from hanging oil, and ensure the repairability and recycling of the tank.

There are machine drawing and manual drawing.

Some drawing tanks are used for machine drawing. The texture of machine drawing is very fine and very shallow. A series of drainage, no oil hanging, scratch prevention and other characteristics are not very obvious. It can only be said that it is better than other mirror light, snowflake sand and other surface treatments. And when some problems are repaired in the follow-up of the sink, it is easy to cause new problems such as uneven surface texture, random lines, yin and Yang color of the sink and so on. The texture of machine drawing is very shallow, which can not discharge water, oil and scratch. A little friction will have an obvious scratch mark.

The process flow of manual wire drawing is to conduct machine wire drawing first, then polish the surface welding trace, and then conduct manual wire drawing.

Here, the advantages of a manual sink are shown. The surface treatment of manual sink is manual wire drawing, with uniform and fine texture, and the more prominent performance is repairability and recycling. That is, after the problem occurs, the product is easy to repair, and the water tank is repaired as new.

The floating rust, rust, corrosion, watermark, scratch and other problems of the sink can be solved with a piece of cleaning cloth. Take a cleaning cloth in your hand, dip some toothpaste, push it along the wire drawing texture of the manual water tank, and simulate the manual wire drawing method, you can make the water tank look new. If the situation is serious, use a small piece 240# of sandpaper at most. Push it with sandpaper first, and then push it with a cleaning cloth.

Post time: Jul-30-2021